Are you wrestling with the complexities of managing and processing data from your Internet of Things (IoT) devices, especially when they're scattered across vast distances? Understanding and implementing remote IoT batch jobs can revolutionize the way you handle your data, unlocking efficiencies and driving innovation you never thought possible.

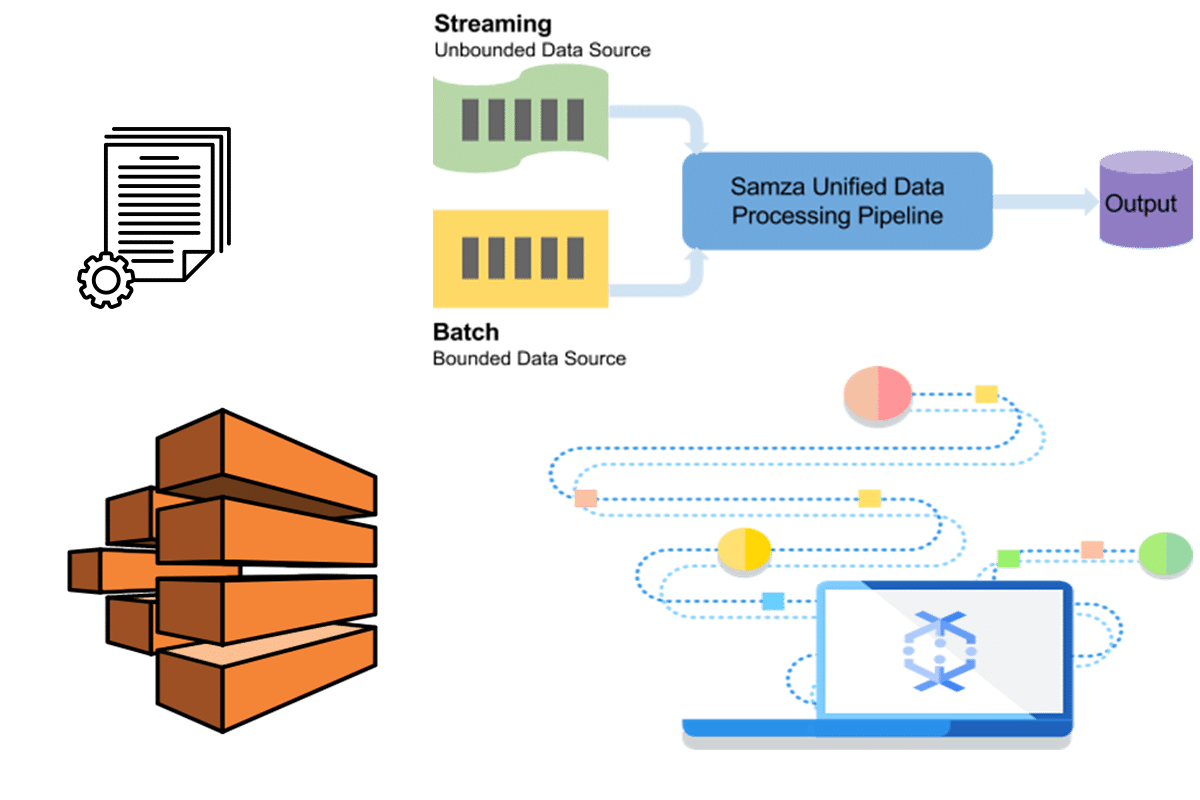

The digital landscape is teeming with interconnected devices, each generating a torrent of data. From smart refrigerators to complex industrial machinery, these devices the heart of the Internet of Things continuously feed information back to central hubs. The sheer volume, velocity, and variety of this data present a monumental challenge. How do we make sense of it all? How do we extract valuable insights that can inform decisions, optimize processes, and drive growth? The answer, in many cases, lies in the power of remote IoT batch jobs.

Let's strip away the jargon and get straight to the core of the matter. A remote IoT batch job, at its heart, is a streamlined process. It's a pre-defined set of instructions or tasks designed to be executed in bulk on IoT devices. The critical distinction here is the "remote" aspect. These tasks are not executed locally on each individual device, but are managed and processed from a central location. Imagine it as a centralized command center, directing operations across a distributed network of intelligent devices.

Read also:Exploring 9xmovies Alternatives What You Need To Know

This approach offers a multitude of advantages. Firstly, it dramatically simplifies data management. Instead of manually configuring and monitoring each device individually, a remote batch job allows you to apply updates, analyze data, and execute commands across a vast network simultaneously. This saves time, reduces the potential for human error, and ensures consistency across the entire IoT ecosystem.

Secondly, it enhances scalability. As your network of IoT devices grows, so too does the volume of data they generate. Remote batch jobs are designed to handle this expansion with ease. They provide the infrastructure needed to process large datasets efficiently, without compromising performance or responsiveness. This is particularly critical in industries where real-time insights are paramount.

Consider the complexities of managing large volumes of IoT data, especially in resource-constrained environments. The need for remote management arises from the inherent limitations of individual IoT devices, which often lack the processing power, storage capacity, and network bandwidth to handle complex tasks on their own. This is where the power of remote IoT batch jobs truly shines.

This architecture allows for the centralization of processing power and data storage, ensuring that even the most complex analytical tasks can be performed with ease. By offloading these tasks to a remote server, the individual IoT devices remain free to focus on their primary function: data collection and transmission.

Let's delve into some practical examples that illustrate the power and versatility of remote IoT batch jobs across different sectors. In the agricultural sector, IoT sensors constantly gather data on soil moisture levels, ambient temperature, and prevailing weather conditions. This information is crucial for optimizing irrigation schedules and maximizing crop yields. A remote IoT batch job could be programmed to analyze this data in real-time and automatically adjust watering systems, ensuring that crops receive the precise amount of water they need, precisely when they need it. This not only conserves water but also reduces costs and enhances agricultural productivity.

In a manufacturing environment, imagine a factory floor bustling with interconnected machinery. IoT sensors are embedded within each piece of equipment, continuously monitoring performance metrics like machine efficiency, energy consumption, and product quality. A remote IoT batch job can analyze this data in real-time, identifying potential bottlenecks, predicting equipment failures, and optimizing production processes. This leads to increased efficiency, reduced downtime, and improved overall profitability.

Read also:Explore 18 Movies More Your Guide To Movierulz Beyond

Consider another scenario: a sprawling smart city. IoT devices are embedded throughout the urban landscape, collecting data on traffic flow, air quality, and public infrastructure. A remote IoT batch job could be used to analyze this data and optimize traffic light timings, monitor pollution levels, and identify areas in need of maintenance. This could result in reduced traffic congestion, improved air quality, and enhanced public safety.

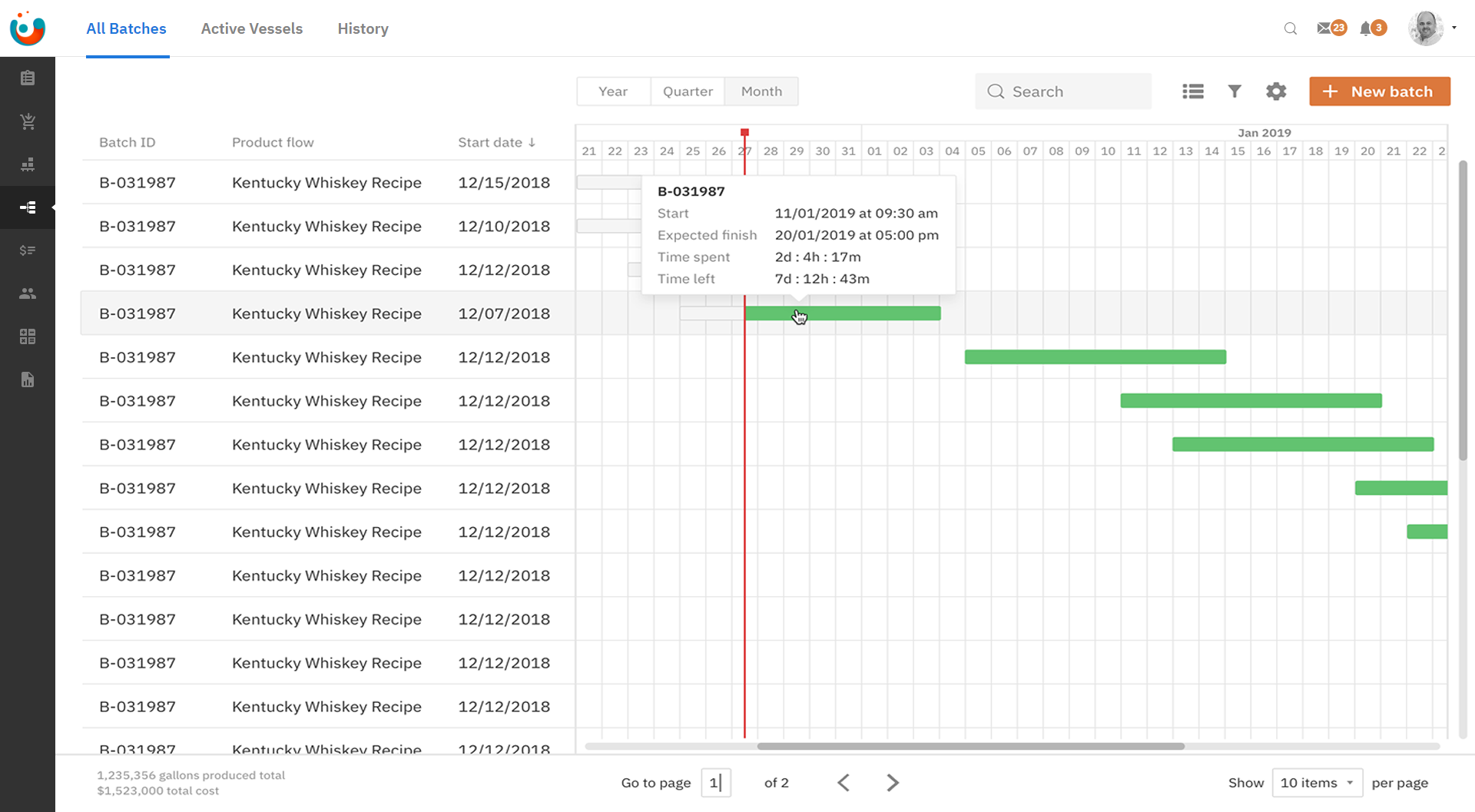

Now, let's consider how remote IoT batch jobs are implemented, with a specific focus on the Amazon Web Services (AWS) platform. AWS provides a comprehensive suite of services that are tailor-made for the deployment and management of IoT applications. These services offer the scalability, reliability, and security that are essential for handling the demands of remote IoT batch processing.

AWS IoT Core serves as the central hub for connecting IoT devices. It provides a secure and scalable platform for devices to connect, send data, and receive commands. Once data is received, it can be processed using various AWS services, such as AWS Lambda, a serverless compute service. AWS Lambda enables you to run code without provisioning or managing servers, making it ideal for processing data in response to incoming events.

AWS IoT Greengrass extends the capabilities of AWS to edge devices. It allows you to run AWS Lambda functions, pre-trained machine learning models, and other software on your devices, even when they are not connected to the internet. This is particularly useful for performing real-time analysis and decision-making at the edge, reducing latency and bandwidth costs.

To illustrate the implementation of a remote IoT batch job on AWS, let's consider a simplified example. Imagine a scenario where IoT sensors are deployed in a fleet of delivery trucks, collecting data on vehicle performance, driver behavior, and cargo conditions. A remote IoT batch job could be designed to perform the following tasks:

Data Collection: The IoT sensors transmit their data to AWS IoT Core. This data might include information such as vehicle speed, fuel consumption, location, and temperature readings from the cargo hold.

Data Storage: AWS IoT Core securely stores this data in an Amazon S3 bucket or Amazon DynamoDB table, providing durable and scalable storage.

Data Processing: An AWS Lambda function is triggered whenever new data arrives. This function analyzes the data, identifies any anomalies (such as excessive speeding or sudden temperature changes), and potentially triggers alerts or notifications.

Reporting and Visualization: Processed data can be visualized using Amazon QuickSight, enabling fleet managers to monitor performance, identify trends, and make data-driven decisions.

Execution: The whole process runs in the background, without any manual intervention, automatically processing the data from the fleet of delivery trucks and generating insights that can be used to optimize operations.

The benefits of this remote IoT batch job are clear. Fleet managers gain real-time visibility into vehicle performance and driver behavior. They can identify areas where improvements can be made, such as optimizing routes, reducing fuel consumption, and ensuring the safe delivery of cargo. This leads to increased efficiency, reduced costs, and improved customer satisfaction.

The implementation of remote IoT batch jobs in AWS empowers organizations to automate their repetitive tasks, while managing the devices in their IoT ecosystem efficiently. By using these tools, organizations can streamline operations, make faster decisions, and improve overall productivity.